Tungsten carbide wire drawing die for drawing ferrous metal wires

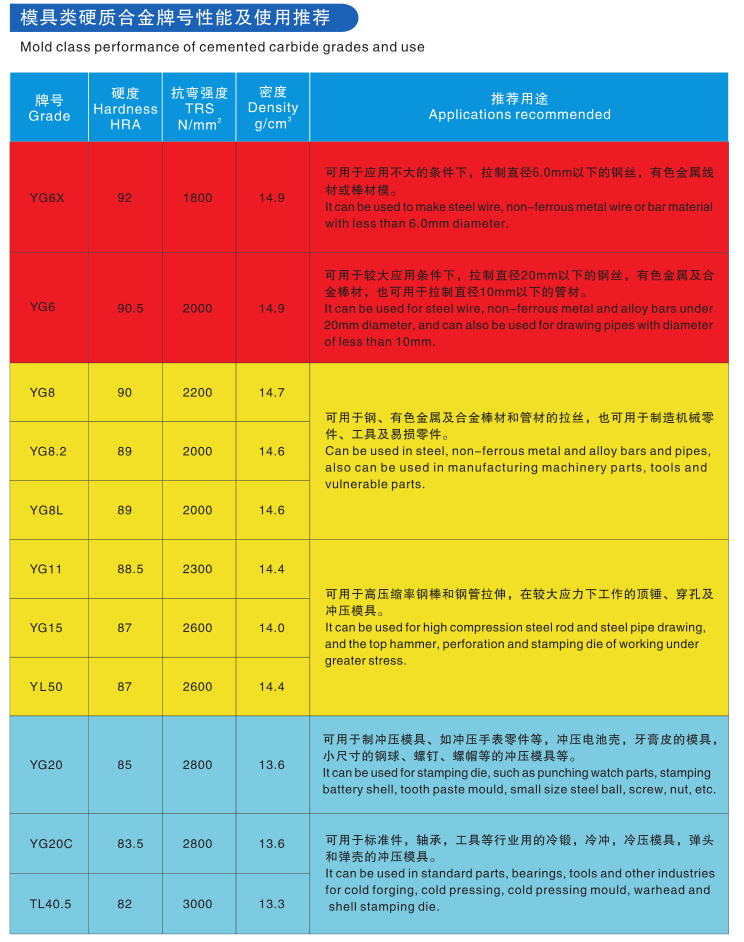

Tungsten Carbide Wire Drawing Dies / cemented carbide wire drawing dies are made from 100% Virgin Raw material of WC and CO. With high density, good wear resistance, and high bending strength. It can be used in wide application field, mainly for powdering, rust removal, cleaning atomizing in the field of chemistry, machinery, architecture etc. Size can be customized.

Cemented carbide wire drawing dies is a special and precision tool which cuts and forms sheet metal into a desired shape or profile. The cutting and forming sections of dies typically are made from special types of hard steel called tool steel. Dies also can contain cutting and forming sections made from carbide or various other hard, wear-resistant materials.

Tungsten carbide punch dies are indispensable in sheet metal processing. Whether it's creating holes or cutting out complex shapes in metal sheets, these punch dies offer excellent cutting performance. Their ability to resist wear ensures that the edges of the punched or cut parts remain sharp and burr - free, which is critical for the subsequent assembly and functionality of metal products.

Overall, tungsten carbide wire drawing die, tungsten carbide cold heading forging dies, and tungsten carbide punch die are the backbone of many manufacturing sectors. Their superior material properties make them the go - to choice for achieving high - precision, high - quality production, and driving forward the progress of the manufacturing industry.

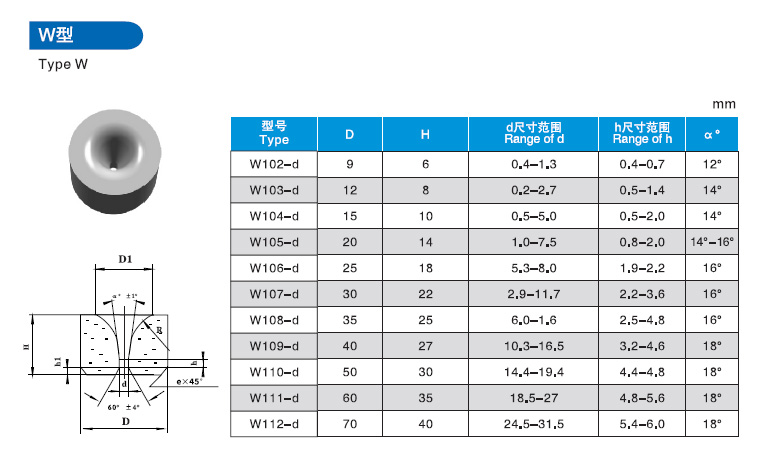

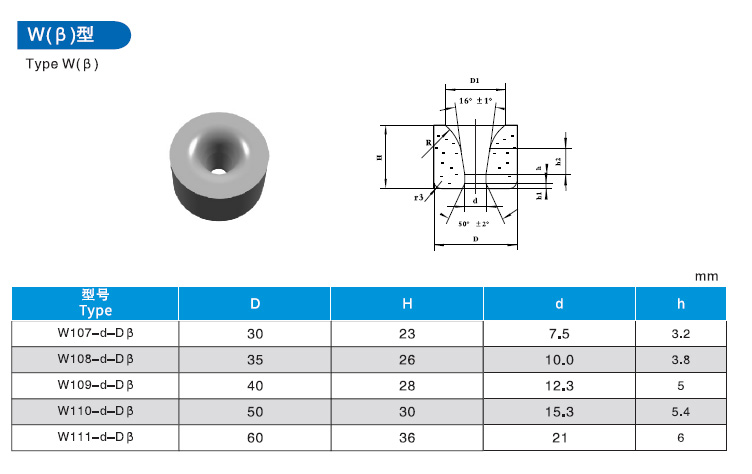

Standard code size of type W carbide drawing die nibs

FAQ

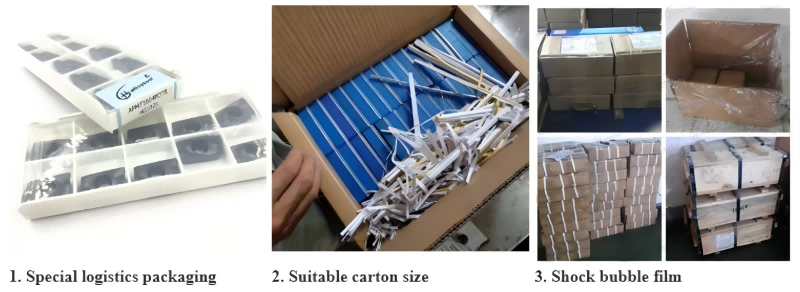

1. How do you ensure product quality?

We've established a rigorous quality control system. Professional quality inspectors monitor every step, from raw material procurement and production processing to finished product delivery. Each batch of products undergoes comprehensive inspections to ensure they meet or exceed industry standards. Additionally, we collaborate with multiple authoritative third - party testing agencies and can provide professional testing reports upon your request.

2. What is the delivery time?

For regular products, we usually have stock available. We can arrange shipment within 3 - 5 working days after receiving your order. For customized products, the delivery time depends on the complexity of the products and the order quantity. We'll confirm the delivery time with you when the order is finalized, usually within 15 - 30 working days. We'll track the production progress in real - time and keep you updated to ensure on - time delivery.

3. What payment methods do you support?

To facilitate your payment, we support multiple mainstream payment methods, including T/T (Telegraphic Transfer), L/C (Letter of Credit), and PayPal. You can choose the payment method that suits you best. If you have any special payment requirements, feel free to communicate with us.

4. Can you provide samples?

Absolutely! We're happy to provide samples for you to evaluate product quality. You only need to cover the sample cost and shipping fees. We'll arrange sample shipment as soon as possible.

5. What if there are quality issues with the products?

If you receive products with quality problems, please contact us immediately and provide relevant photos or videos as evidence. We'll verify the situation right away, offer free return or exchange services, and bear the corresponding shipping costs. Meanwhile, we'll conduct an in - depth analysis of the root cause and take effective measures to prevent similar issues from occurring again.