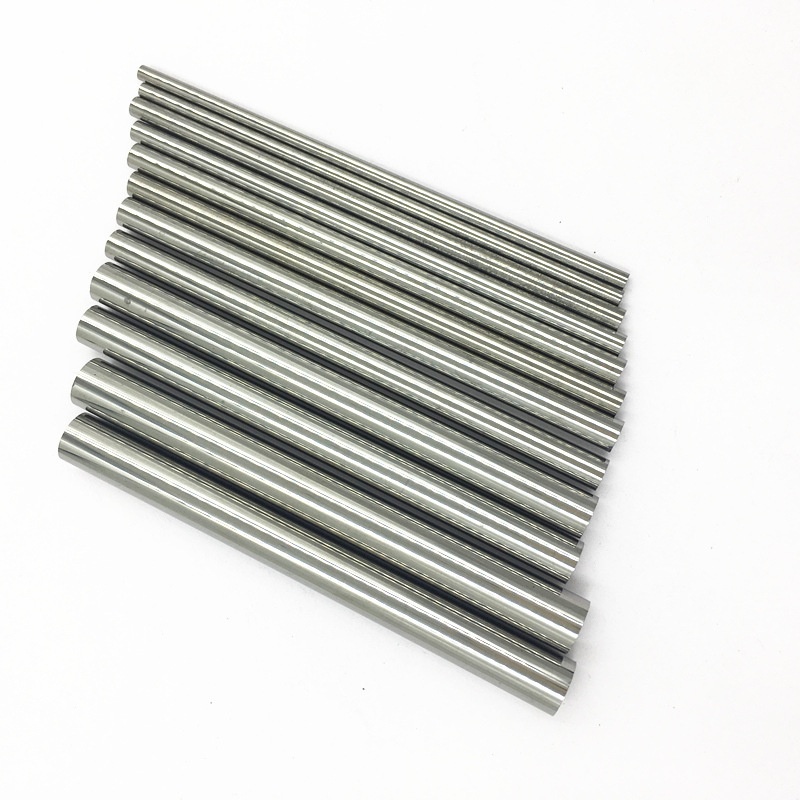

Product name : Tungsten Carbide Bar

Product No. : Tungsten Carbide Bar

Details:

Tungsten Carbide Round Bars: Versatile Workhorses in Industrial Fields

Tungsten carbide round bars stand as indispensable base materials in the vast landscape of industrial manufacturing. These bars, composed primarily of tungsten carbide (WC) with cobalt (Co) as a binder, are fabricated via powder metallurgy, leveraging their unique microstructure to become core carriers in machining operations.

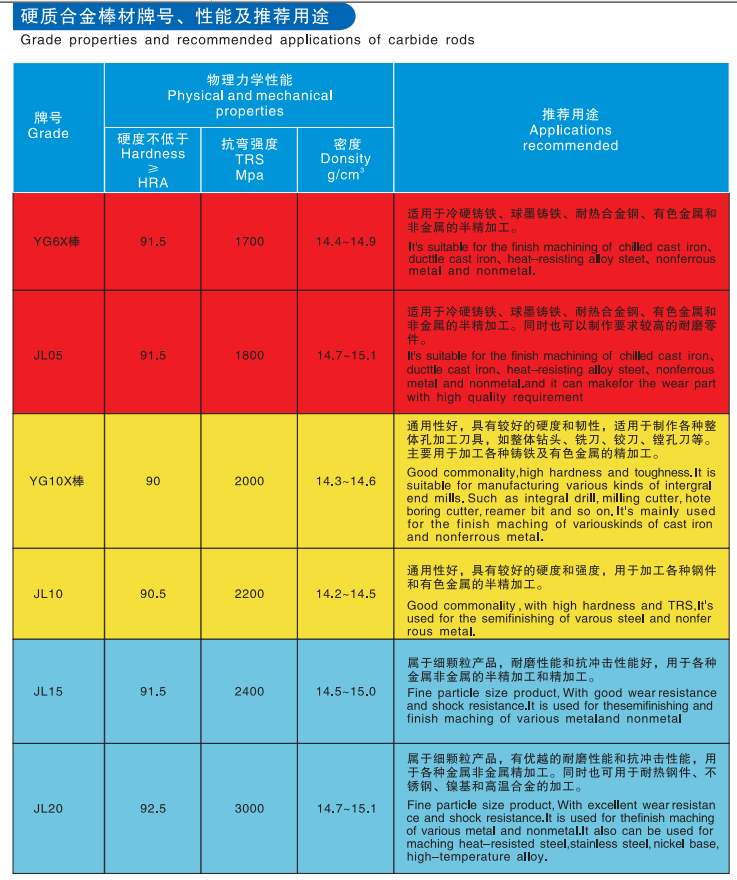

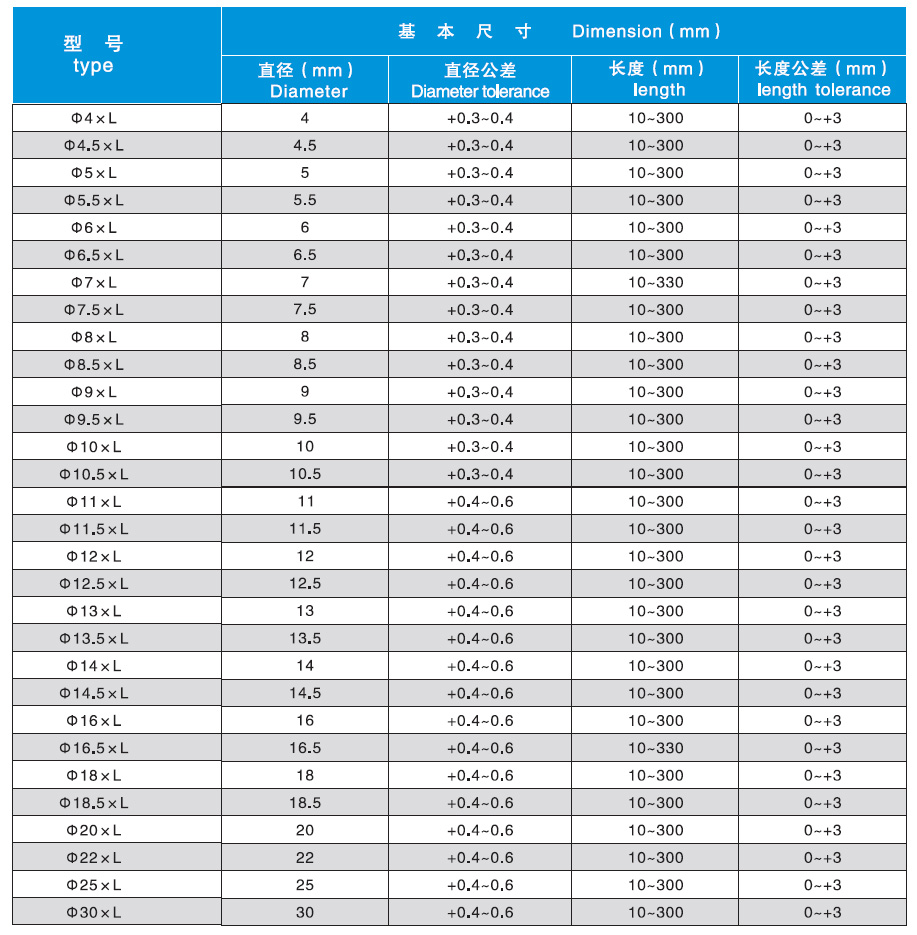

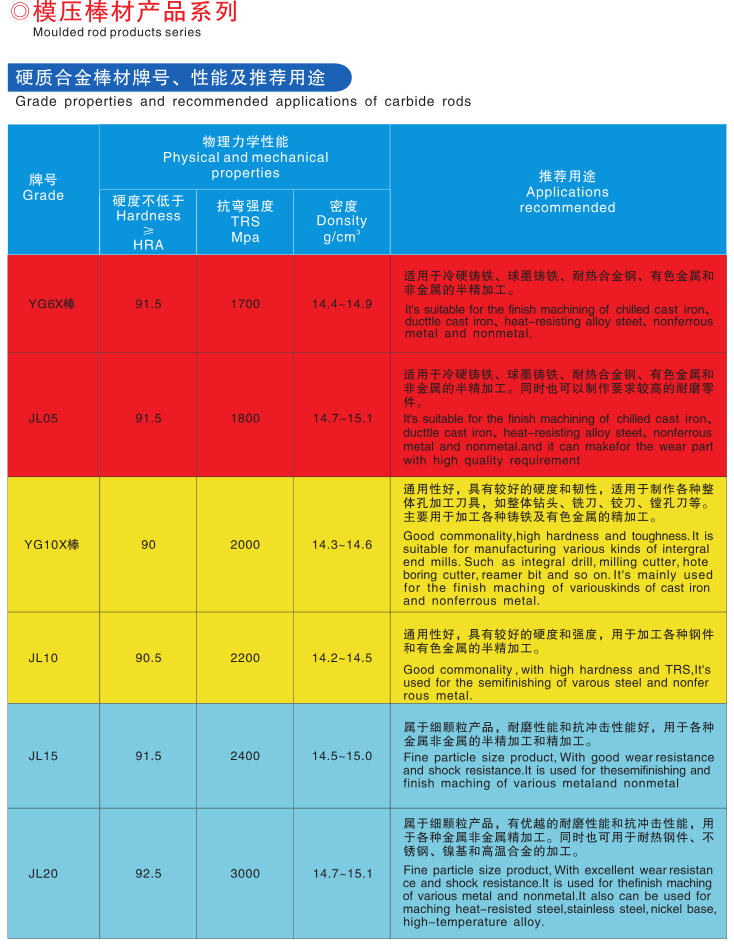

The performance advantages of tungsten carbide round bars are extremely prominent: with a hardness of 89–93HRA, they far exceed ordinary metal materials, enabling efficient cutting of hard materials like quenched steel; their wear resistance is 10–20 times that of high-speed steel, maintaining dimensional stability in severe wear scenarios such as mining drilling; and their compressive strength of up to 6000MPa ensures they resist deformation under compressive loads in applications like mold ejector pins. These properties make tungsten carbide round bars industrial "tools" that balance hardness and toughness.

In terms of production processes, manufacturing tungsten carbide round bars involves strict procedures: first, micron-level tungsten carbide and cobalt powders are uniformly mixed, formed into blanks by isostatic pressing, and then sintered at temperatures above 1400°C to create a dense structure. To meet high-end applications, some tungsten carbide round bars undergo TiN coating treatment, raising surface hardness to over 2500HV and significantly extending service life.

In practical applications, tungsten carbide round bars are ubiquitous across industrial sectors: in machining, they are made into twist drills, end mills, and other cutting tools for metal hole processing and contour milling; in mold manufacturing, tungsten carbide round bars serve as core components, withstanding high-pressure melt erosion in injection molds; during oil exploration, drill bits welded with tungsten carbide round bars efficiently break rock. Statistics show that approximately 30% of global tungsten carbide round bars are used for cutting tools annually, 25% for mold manufacturing, and the rest serve special fields like mining and aviation.

With the advancement of intelligent manufacturing, tungsten carbide round bars are evolving toward ultrafine graining and diversified coatings. For example, nanocrystalline tungsten carbide round bars exhibit 40% higher wear resistance than traditional products, while gradient coating technology maintains red hardness during high-temperature cutting. In the future, this multifunctional material will continue to empower high-end manufacturing with superior performance and cost advantages.

Related Products: